Typhoon Bolt Caps - Ultimate protection against fire & corrosion

Bolt caps - Quick, quality fire protection & can be applied in any weather.

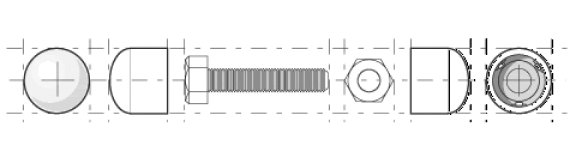

Product InformationBolt caps give a unique opportunity to provide total protection to bolted connections, assessed and approved by the Steel Construction Institute.

Engineered to Cost effectively provide simple easy and quick installation in any weather to give the best fire & corrosion protection to one of the most crucial parts of any structure - the bolted connection.

Tested, evaluated & demonstrated to give up to 3 hours cellulosic, 4 hours hydrocarbon and 2 hours jet fire protection with no volatile emission on site and tested for a 1000 hours to ASTM D117.

On a range of projects, such as iconic buildings, oil and gas installations, airports, pharma plants and other demanding asset protections applications.

No market equivalents able to offer this range of benefits and available in metric and imperial sizes to suit a range of bolt types and custom shapes if required.

Bolt caps have the potential to be reusable and there is no onsite VOCs

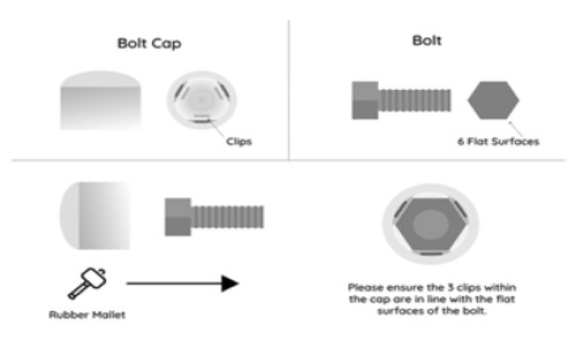

Quick and easy to apply - protection in seconds

Any weather application - giving speed of build

Quick & easy inspection of protected joints & cyclic bolt inspection if needed

Consistent quality to all connections

Health & Safety benefits - less working time at height

Large Range of metric, imperial and custom sizes and shapes available

No VOC's on site